GibbsCAM is a cutting-edge CAM system for programming CNC machine tools. GibbsCAM has the power and flexibility to let you make parts the way you want. With its shop-friendly interface that is easy to navigate, you’ll maximize productivity. Whether CNC programmer, machinist or manufacturing engineer, the user will find familiar terminology. Icons will make sense. Processes will be logical. With GibbsCAM, CNC programming is flexible, fast, reliable, and efficient.

Mill, Drill, Turn, Burn—GibbsCAM Does it All

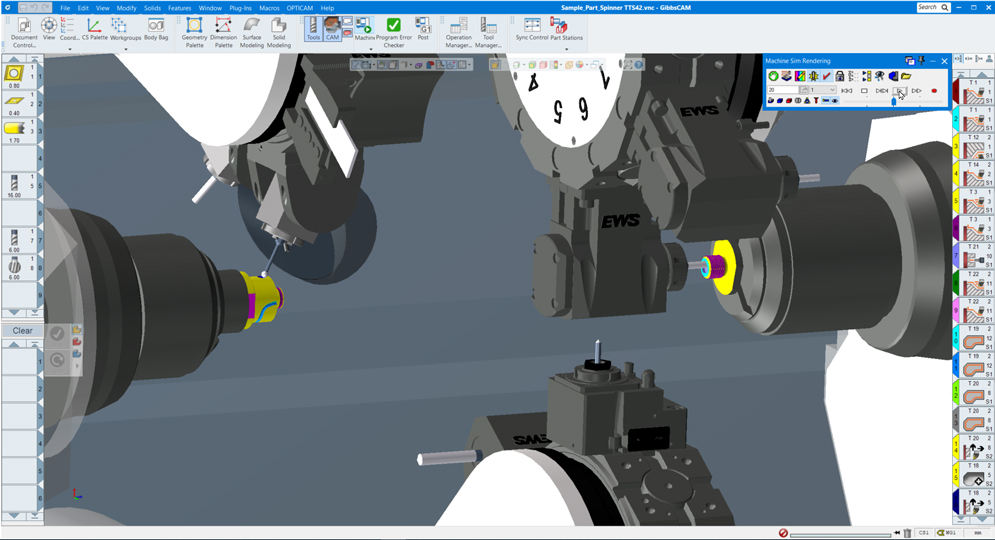

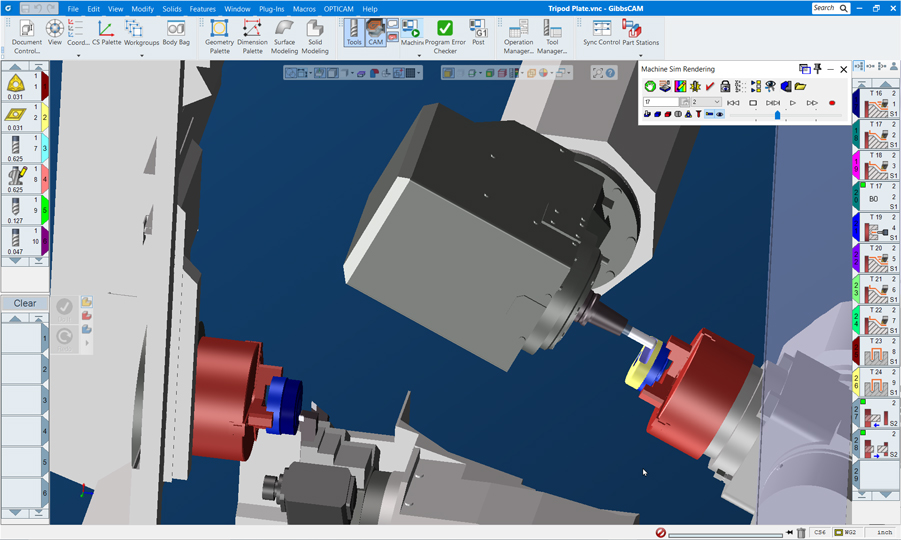

GibbsCAM programs any CNC milling, turning, mill-turn or wire EDM machine. From 2-axis turning and 2.5 axis milling, to 3-, 4- and 5-axis simultaneous and the most complex multi-spindle, multi-turret, multi-tasking and Swiss-style MTM machines, GibbsCAM drives them all.

Programmers Get Up to Speed Fast

The interface icons are easily understood, and the menu structure is flat, so programmers don’t have to step through menu after menu to get something done. It enables quick navigation and fast programming for experienced programmers and rapid learning for new programmers.

Seamless Integration with Any CAD System

Whatever CAD format your customers, designers or engineers prefer to use, that’s the format that GibbsCAM will read or open directly and accurately, so you can quickly modify part models for machinability.

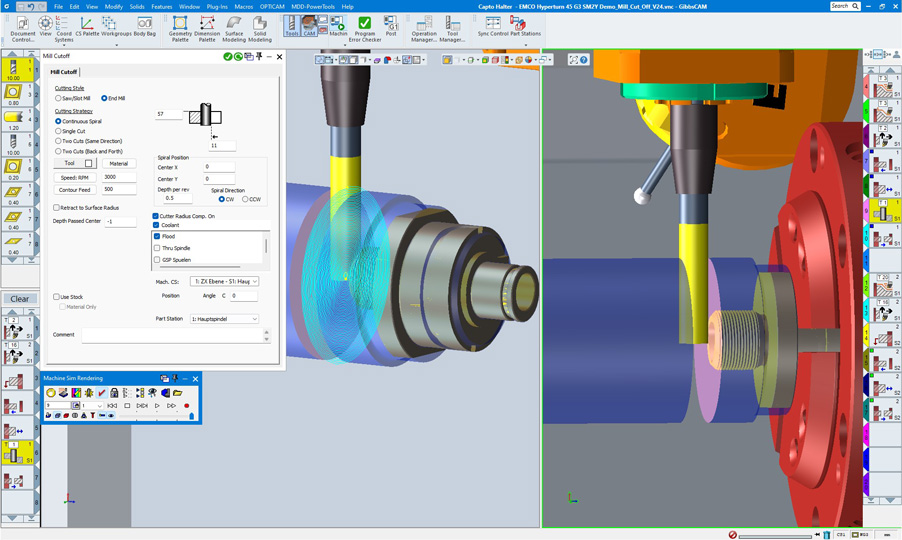

Accurate, Flexible and Reliable Toolpath Creation

Reads, translates, creates, modifies and machines part features with precision. Provides multiple ways to drive cutting tools, including high-speed machining strategies, so parts can be programmed and machined your way. Saves tools and processes so you can quickly program a family of parts or react to engineering without having to reprogram the entire part.

Toolpath Verification

Toolpath simulation with collision detection, which is available at any point in the programming, shows tool motion and rendered surface finish, highlighting gouges and unwanted cuts for fast error correction.

Accurate Machine Simulation

From the most complex multi-axis machine, to the simplest, GibbsCAM Machine Simulation can prevent costly errors at the machine, and greatly reduce on-machine prove-out.

Error-free Post Processors

Take advantage of the huge library of over 13,000 error-free post processors created and maintained by Gibbs, or have Gibbs create post processors for you, to precisely match your requirements.

Grows with You

Just buy the options you need today, and add optional functionality as you buy new machines. New capabilities integrate directly into the interface and menus your programmers already know.

Backed by Exceptional Support

Your local GibbsCAM Reseller is always there to assist you, but if for any reason their technical experts are not immediately available, GibbsCAM Technical Support has you covered.

Lowers Costs, Increases Profit

GibbsCAM was developed to be efficient for the programmer, efficient for the machinist, and efficient at the machine. With GibbsCAM you’ll get more programs done faster. You’ll get higher accuracy and reliability. You’ll spend less time testing and proving programs. You’ll get faster cycle times and more parts out the door, to keep more customers satisfied. With GibbsCAM, you have a winning solution!

Maximize Your Investment

Want to make sure you are maximizing your investment? Ensure that you gain programming capability, efficiency and a competitive edge by keeping your GibbsCAM software current with the GibbsCAM Maintenance Program.